Aerospace & Defense Circuit Board Manufacturer

AdvancedPCB is a trusted military PCB manufacturer supporting aerospace & defense electronics where reliability, traceability, and compliance are mandatory. We build aerospace & defense PCBs for programs that must perform under extreme thermal cycling, vibration, shock, and long service life requirements.

Our team works directly with design engineers to translate complex layouts into manufacturable hardware that qualifies cleanly and performs reliably in regulated environments.

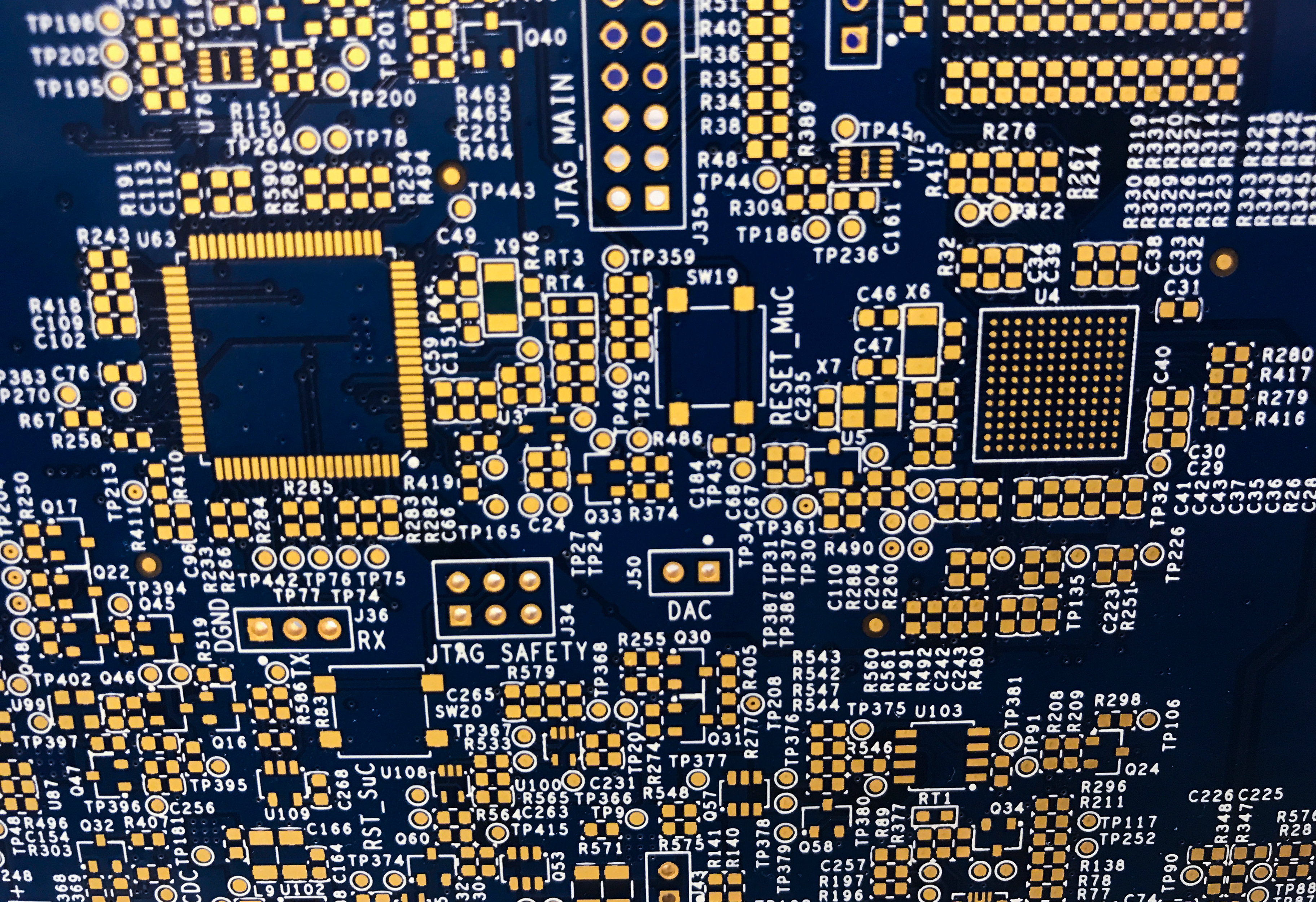

Aerospace & Defense PCB Technologies

We support the advanced technologies commonly required in PCB aerospace and defense applications, including:

High-reliability, multilayer PCB designs

HDI designs with microvias and sequential lamination

Rigid-flex and flex circuits for space and weight constrained designs

Controlled impedance and high-speed signal integrity structures

High-temperature and specialty materials for harsh environments

Each aerospace PCB is built using controlled processes and full traceability to support regulated programs.

Why Aerospace& Defense Engineers Partner with AdvancedPCB

Aerospace and defense designs are constrained by certification, materials, and process limits long before fabrication begins. AdvancedPCB helps engineers address those constraints early.

We focus on:

Process-driven reliability, aligned to aerospace and military standards

Early DFM collaboration to reduce layout-driven respins

Repeatable, documented builds aligned to mil spec PCB and IPC Class 3 requirements

By engaging early, we help reduce qualification risk, shorten development cycles, and improve first-pass success.

Certifications and Compliance for Aerospace & Defense

Certifications define how aerospace and defense PCBs are designed, built, inspected, and documented. AdvancedPCB operates under quality systems and standards commonly required for military and aerospace programs, including:

ISO 9001: 2005, AS9100D, ITAR registration

MIL-PRF-31032, MIL-PRF-55110

IPC Class 3 and more. Read full list of certifications.

These certifications support consistent manufacturing, audit readiness, and long-term program sustainment. Additionally, AdvancedPCB regularly supports DOD requirements.

AdvancedPCB is at an elite level in information security and is on track for CMMC compliance at all sites.

Aerospace & Defense PCB Assembly for Prototypes

AdvancedPCB provides aerospace PCB assembly services focused on prototype and early-stage builds. This offering is designed for engineers validating new designs prior to qualification.

Prototype assembly supports:

First-article and NPI builds.

Full turnkey, partial turnkey or consignment services.

Quotes in 2 hours with standard turn-times of 3-5 days or faster.

No minimum order quantities.

This approach help engineers move from design to validated hardware with greater confidence.

Featured Resource: Military PCB Certifications Guide

Understanding how certifications impact materials, stackups, inspection, and supplier selection is critical for aerospace and defense engineers.

This technical guide explains:

Key aerospace and defense PCB certifications

How certifications affect design and fabrication decisions

Common pitfalls that delay qualification

Secure, US-Based Manufacturing

All manufacturing is performed domestically to protect intellectual property and meet regulatory obligations. AdvancedPCB is recognized for delivering aerospace-approved PCB solutions built under controlled processes, rigorous inspection, and full traceability. Our national footprint allows us to support geographically distributed programs while maintaining consistent quality.

With decades of experience delivering aircraft PCBs and defense electronics, we understand the documentation, auditing, and validation requirements demanded by regulated industries. Customers trust our repeatability across both low-volume and high-mix programs

Secure File Transfer

For AdvancedPCB to best represent and protect your data we ask for your compliance with the following:

- Please take measures to mark your unclassified information as CUI, in advance of sharing.

- When sharing information, we must transmit through a secured portal/file transfer protocol (FTP). We cannot transmit CUI information via email, only via secured portal.

- AdvancedPCB can use the customer provided secure portal.

- OR you can contact us to request a secure, temporary link for the Serv-U File Sharing platform. Once requested, you will receive an automated email containing the credentials necessary to securely upload your project files.

.png)