Moving From Prototypes to Large-Scale Production

A competitive challenge electronics companies face is quickly moving from concept to product. No matter the application, you must take your project through the design/ redesign, prototype, and scale lifecycle at speed. You can see the Advanced PCB (APCB) cycle for this process in Figure 1.

Figure 1: APCB’s solution for building prototypes and pre-production production ramps to high-volume production and redesign. This process utilizes both domestic and global facilities.

While businesses generally have the expertise and in-house knowledge to go from concept to circuit, ensuring the board layout is viable and manufacturable is a different challenge. After the prototype phase, companies move toward seeking options for high-volume manufacturing. APCB has the expertise, legacy, and infrastructure to support a range of operations through its domestic and offshore facilities. The domestic facilities support simple and complex builds, and the offshore facilities allow companies to scale to high-volume production. As a result, companies can rapidly create a design concept, and take the board into production, potentially utilizing global facilities with lower manufacturing costs. This tutorial discusses how APCB facilitates the process from quick-turn prototype to mass production.

Building A Prototype

Design and Layout

There are three stages to realizing a PCB prototype: design, board creation, and assembly. Not all designs start from scratch, oftentimes there is a redesign of a previous board for functional optimization, size reduction, ensuring industry standards, and more. Many design firms design their boards from circuit to layout. The circuit design offers two main outputs that guide the rest of the product development cycle: the board artwork and the assembly data. The board artwork and layout are a crucial step in ensuring the product can be readily integrated into its application. It may need to be optimized in terms of size through the layout of components and traces or with new materials in rigid, Rigid-Flex, or Flex topologies. Other layout design strategies might need to be implemented to improve signal integrity (SI) or meet existing EMC requirements in high-speed digital or high-density interconnect (HDI) designs. While many engineers who specialize in building products for specific use cases can accomplish this in-house, APCB offers this service through its San Diego facility with IPC-certified interconnect designer (CID and CID+) personnel who have established layout expertise.

Fabrication

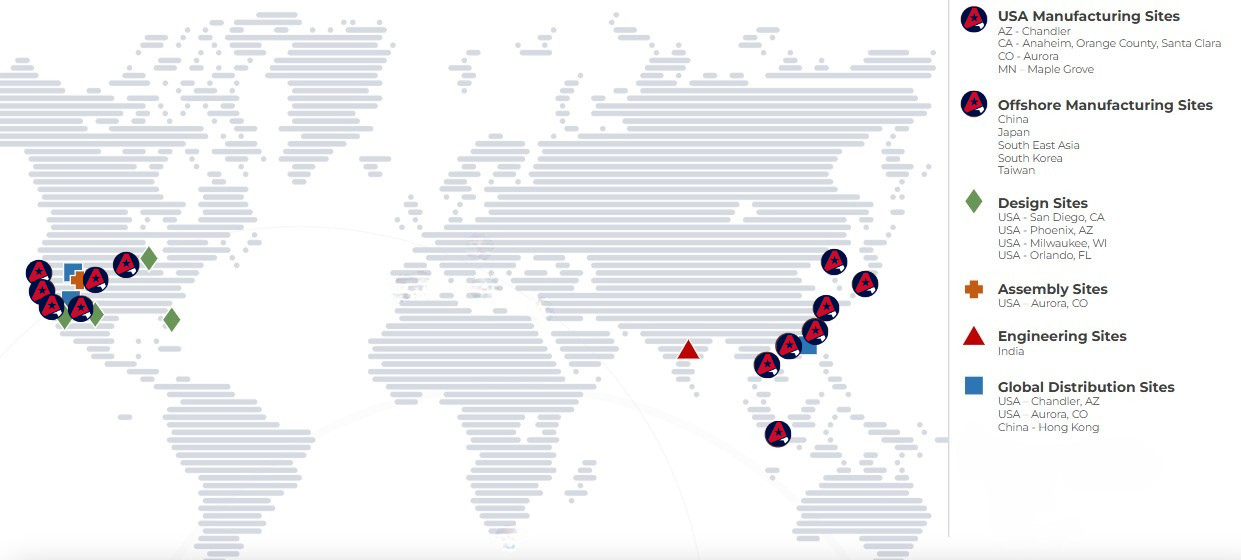

APCB has the manufacturing capabilities to turn designs into manufactured boards with reliable execution, without compromising on quality. Seven manufacturing facilities are equipped to build prototype products for a standard rigid through-hole, high-density interconnect (HDI) with blind/buried/stacked vias, or Flex/Rigid-Flex at speed. Figure 2 shows a map of APCB’s domestic and offshore manufacturing sites.

.png)

Figure 2: APCB’s domestic and offshore manufacturing sites, design sites, assembly sites, engineering sites, global distribution sites, and global sales offices.

You can see the capabilities of the USA-based manufacturing facilities in Table 1. The domestic abilities are robust and provide the benefit of accelerated production cycles. APCB can offer quick-turn boards as soon as the next day for standard multi-layer (4-6 layer) rigid boards. For more complex boards, there are still quick-turn schedules, but they require increased communication with the designer and the front-end engineering of the specific APCB facility that focuses on that board type (e.g., HDI, Flex, Rigid-Flex).

Table 1: APCB’s 6 domestic manufacturing sites and their respective capabilities.

Assembly

The second output of the design is the data related to the assembly. This grants users the bill of materials (BOM), which lists the components used as well as their locations on the board. The assembly can be done in-house, with a third-party contractor, or with APCB. Once the assembly is complete, the finished board outputs a modified set of electrical signals from an input signal(s).

Moving Toward Large-Scale Production

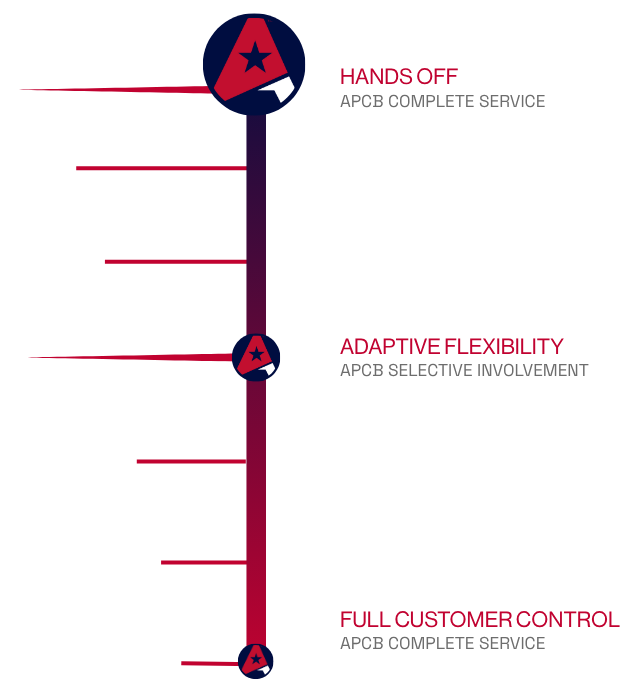

After the final design has been verified and is seen as a viable product, a business must scale to production. APCB offers a route to larger-scale offshore production with a spectrum of support. You can assume full control of all offshore manufacturing with APCB helping when needed, you can “hand off” to APCB allowing them to complete the service, or you can choose somewhere in the middle with selective involvement from APCB (Figure 3).

.png)

Figure 3: APCB’s global program solutions allow you to choose the level of support and control that you would like to have over offshore production.

Global Supply Chain Risks

A primary focus of modern tech companies is to innovate and deliver cutting-edge solutions to enhance electronics. The list of new technologies is abundant, and so are the demands. It can be difficult for these companies, especially new businesses, to pivot their focus to introduce the right teams that can assess the technical, support, and logistical details of a global supply chain. Table 2 presents several risks that come with implementing a supply chain.

| Risk | Potential Consequence |

| Manufacturing lower-end technology in a higher-end facility | Incurring unnecessary costs |

| Manufacturing higher-end technology in a lower-end facility | Low production yield |

| Going with a broker or manufacturer that does not specialize in your product area and does not do an upfront intake profile to understand your needs | Production issues if the company cannot qualify and/or visit offshore manufacturing facilities frequently |

| Insufficient communication between the engineering staff that created the product prototype and the volume production engineering team | Potential defects in a whole production run, allowing competitors to have an advantage |

| Insufficient communication between the engineering staff that created the product prototype and the volume production engineering team | Lower production yield and slower time to market (TTM) |

| Working without inventory management | Difficulty turning a product into an off-the-shelf commodity, leading to longer lead times |

| The supplier cannot deliver during transportation disruptions | Product is not delivered in time anytime there are service disruptions. This delay becomes more significant when having to clear customs for international shipments. |

Table 2: A few potential risks and consequences that come with having a global supply chain.

Risk Mitigation with APCB

APCB is an experienced supplier that addresses supply chain risks head-on. With many pre-qualified and approved facilities to choose from, both domestic and offshore, APCB can match the technology to the factory to maximize customer yield by obtaining the best solution at the lowest cost.

APCB has manufacturing, engineering, and full-service staff to oversee all production in offshore facilities. Products from offshore facilities that are involved with volume production are shipped back to APCB domestic facilities for inspection and compliance review. If any defects or concerns appear in this process, APCB domestic facilities will assume the rest of the volume manufacturing to ensure the PCB is fabricated according to industry standards. Furthermore, all APCB offshore facilities undergo a qualification process and maintain their own UL and ISO certifications, with several achieving TS, AS, or medical certifications.

APCB also has flexible stocking programs (Figure 4) that allow customers to warehouse products in APCB’s distribution center or achieve custom stocking solutions. Vendor Managed Inventory (VMI) and Kanban inventory management programs are supported for “just in time” assemblies on custom PCBs. Finally, APCB is an experienced supplier that has pre-existing, dependable relationships with multiple carriers, allowing for more transportation options if one mode of transport is not available.

Summary

To keep up the pace with advancements, modern technology companies must be able to realize their design concept from the circuit, layout, first-run fabrication, and working prototype, all the way to pre-production ramp-ups and high-scale production. To do this successfully, it is important to work with an experienced PCB manufacturer who has comprehensive solutions with extensive engineering, manufacturing, production, and transportation expertise. APCB has the legacy and established facilities that can readily assist companies in building a product from the ground up. APCB offshore facilities welcome on-site or virtual audits with on-site program managers in Asia, and has a global team that is readily available to help. For more information visit https://www.advancedpcb.com/en-us/services/global-services/.

Related Posts

.png?resizemode=force&maxsidesize=1226)

A step-by-step guide to building a standard rigid, multi-layer PCB

Future trends of the circuit board